Kwiveki engaphambili, sazise inkqubo yokujika kwee-capacitors zefilimu, kwaye kule veki ndingathanda ukuthetha ngetekhnoloji ephambili yee-capacitors zefilimu.

1. Itekhnoloji yokulawula uxinzelelo rhoqo

Ngenxa yesidingo sokusebenza kakuhle, ukujija kudla ngokuba kubude obuphezulu ngokubanzi kwii-microns ezimbalwa. Kwaye indlela yokuqinisekisa ukuxinana okungapheliyo kwezinto zefilimu kwinkqubo yokujija ngesantya esiphezulu ibaluleke kakhulu. Kwinkqubo yoyilo akufuneki siqwalasele ukuchaneka kwesakhiwo soomatshini kuphela, kodwa sikwanayo nenkqubo yolawulo lokuxinana egqibeleleyo.

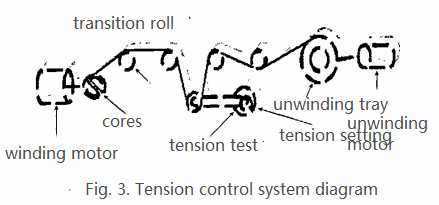

Inkqubo yolawulo ngokubanzi inamacandelo aliqela: indlela yokulungisa uxinzelelo, isenzi sokubona uxinzelelo, imoto yokulungisa uxinzelelo, indlela yokutshintsha, njl. Umzobo wesicwangciso senkqubo yokulawula uxinzelelo uboniswe kuMfanekiso 3.

Ii-capacitor zefilimu zifuna ukuqina okuthile emva kokujijela, kwaye indlela yokuqala yokujijela kukusebenzisa intwasahlobo njengodamping ukulawula uxinzelelo lokujijela. Le ndlela iya kubangela uxinzelelo olungalinganiyo xa i-motor yokujijela ikhawuleza, iyancipha kwaye ima ngexesha lenkqubo yokujijela, nto leyo eya kubangela ukuba i-capacitor iphazamiseke okanye ikhubazeke lula, kwaye ukulahleka kwe-capacitor nako kukhulu. Kwinkqubo yokujijela, uxinzelelo oluthile kufuneka lugcinwe, kwaye le fomula yile ilandelayo.

F=K×B×H

Kule fomyula:F-Uvavanyo

K-I-Tesion coefficient

B-Ububanzi befilimu(mm)

H-Ubukhulu befilimu (μm)

Umzekelo, uxinzelelo lobubanzi befilimu=9 mm kunye nobukhulu befilimu=4.8μm. Uxinzelelo lwayo yi:1.2×9×4.8=0.5(N)

Ukusuka kwi-equation(1), uluhlu loxinzelelo lunokufunyanwa. Intwasahlobo ye-eddy ene-linearity elungileyo ikhethwa njenge-tension setting, ngelixa i-non-contact magnetic induction potentiometer isetyenziswa njenge-tension feedback detection ukulawula i-output torque kunye ne-direction ye-DC servo motor ekhululayo ngexesha le-winding motor, ukuze uxinzelelo luhlale luhleli kuyo yonke inkqubo yoxinzelelo.

2. Itekhnoloji yokulawula ukujikajika

Umthamo wee-capacitor cores unxulumene kakhulu nenani leenguqu zokujika, ngoko ke ulawulo oluchanekileyo lwee-capacitor cores luba yiteknoloji ebalulekileyo. Ukujika kwe-capacitor core kudla ngokwenziwa ngesantya esiphezulu. Ekubeni inani leenguqu zokujika lichaphazela ngokuthe ngqo ixabiso lomthamo, ulawulo lwenani leenguqu zokujika kunye nokubala kufuna ukuchaneka okuphezulu, okuhlala kufezekiswa ngokusebenzisa imodyuli yokubala ngesantya esiphezulu okanye isenzi esinobuchaneko obuphezulu bokufumanisa. Ukongeza, ngenxa yemfuneko yokuba uxinzelelo lwezinto lutshintshe kancinci kangangoko ngexesha lenkqubo yokujika (ngaphandle koko izinto ziya kushukuma ngokungenakuphepheka, zichaphazele ukuchaneka komthamo), ukujika kufuneka kusebenzise iteknoloji yolawulo esebenzayo.

Ulawulo lwesantya oluhlukaniswe ngokwezigaba kunye nokukhawulezisa/ukunciphisa isantya ngokufanelekileyo kunye nokucubungula isantya esiguquguqukayo yenye yeendlela ezisebenzayo ngakumbi: isantya sokujika esihlukeneyo sisetyenziswa ngamaxesha ahlukeneyo okujika; ngexesha lesantya esiguquguqukayo, ukukhawulezisa kunye nokuhla kwesantya kusetyenziswa kunye neejika zesantya eziguquguqukayo ezifanelekileyo ukuphelisa i-jitter, njl.

3. Itekhnoloji yokususa isinyithi

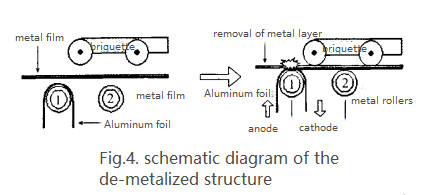

Iileya ezininzi zezinto zibotshelelwe phezu komnye nomnye kwaye zifuna unyango lokutywina ubushushu ngaphandle nangaphandle. Ngaphandle kokwandisa izinto zefilimu yeplastiki, kusetyenziswa ifilimu yesinyithi ekhoyo kwaye kusetyenziswa ifilimu yayo yesinyithi kwaye ipleyiti yayo yesinyithi isuswa ngendlela yokususa isinyithi ukuze kufunyanwe ifilimu yeplastiki ngaphambi kwetywina langaphandle.

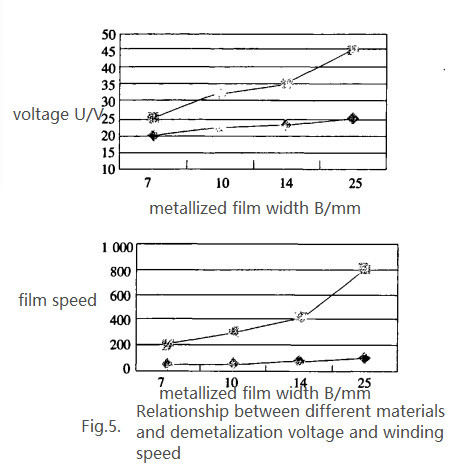

Le teknoloji inokonga iindleko zezinto kwaye kwangaxeshanye inciphise ububanzi bangaphandle be-capacitor core (kwimeko efanayo nomthamo we-core). Ukongeza, ngokusebenzisa iteknoloji yokususa i-metalization, i-metal coating yomaleko othile (okanye iileya ezimbini) zefilimu yesinyithi inokususwa kwangaphambili kwi-core interface, ngaloo ndlela kuthintelwe ukwenzeka kwe-short circuit eyaphukileyo, enokuphucula kakhulu isivuno se-coiled coils. Ukusuka kuMfanekiso 5, kunokugqitywa kwelokuba ukuze kufezekiswe isiphumo esifanayo sokususa. I-voltage yokususa yenzelwe ukuba ihlengahlengiswe ukusuka kwi-0V ukuya kwi-35V. Isantya kufuneka sincitshiswe sibe phakathi kwe-200r/min kunye ne-800 r/min yokususa i-metalization emva kokujikeleza ngesantya esiphezulu. I-voltage eyahlukileyo kunye nesantya zinokusetwa kwiimveliso ezahlukeneyo.

4. Itekhnoloji yokutywina ubushushu

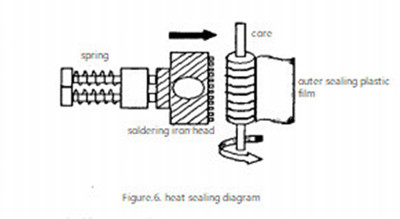

Ukuvalwa kobushushu yenye yezona teknoloji ziphambili ezichaphazela ukufaneleka kwee-wound capacitor cores. Ukuvalwa kobushushu kukusebenzisa intsimbi yokunyibilikisa enobushushu obuphezulu ukukrwela nokubopha ifilimu yeplastiki kwindawo ephakathi kwe-coiled capacitor core njengoko kubonisiwe kuMfanekiso 6. Ukuze i-core ingasongwanga ngokukhululekileyo, kufuneka ibotshelelwe ngokuthembekileyo kwaye ubuso bokugqibela bube tyaba kwaye buhle. Izinto ezininzi eziphambili ezichaphazela isiphumo sokuvalwa kobushushu bubushushu, ixesha lokuvalwa kobushushu, ukuqengqeleka kwe-core kunye nesantya, njl.

Ngokubanzi, ubushushu bokuvala ubushushu buyatshintsha ngokobukhulu befilimu kunye nezinto ezisetyenzisiweyo. Ukuba ubukhulu befilimu yezinto ezifanayo yi-3μm, ubushushu bokuvala ubushushu buphakathi kwe-280℃ kunye ne-350℃, ngelixa ubukhulu befilimu buyi-5.4μm, ubushushu bokuvala ubushushu kufuneka buhlengahlengiswe bube yi-300cc kunye ne-380cc. Ubunzulu bokuvala ubushushu bunxulumene ngokuthe ngqo nexesha lokuvala ubushushu, iqondo lokuqhekeka, ubushushu besinyithi esinyibilikayo, njl. Ukuqonda ubunzulu bokuvala ubushushu kubaluleke kakhulu ukuba ingaba ii-capacitor cores ezifanelekileyo zinokuveliswa na.

5. Isiphelo

Ngophando nophuhliso kwiminyaka yakutshanje, abavelisi abaninzi bezixhobo zasekhaya baye baphuhlisa izixhobo zokugquma ii-capacitor zefilimu. Uninzi lwazo lungcono kuneemveliso ezifanayo ekhaya nakwamanye amazwe ngokubhekiselele kubukhulu bezinto, isantya sokugquma, umsebenzi wokususa isinyithi kunye noluhlu lwemveliso yokugquma, kwaye zikumgangatho wetekhnoloji ophucukileyo wamazwe ngamazwe. Nantsi inkcazo emfutshane yetekhnoloji ephambili yetekhnoloji yokugquma ii-capacitor zefilimu, kwaye sinethemba lokuba ngenkqubela phambili eqhubekayo yetekhnoloji enxulumene nenkqubo yokuvelisa ii-capacitor zefilimu zasekhaya, sinokuqhuba uphuhliso olunamandla lweshishini lezixhobo zokuvelisa ii-capacitor zefilimu eTshayina.

Ixesha lokuthumela: Matshi-15-2022