Kule veki siza kuhlalutya ukusetyenziswa kwee-capacitors zefilimu endaweni yee-capacitors ze-electrolytic kwii-capacitors ze-DC-link. Eli nqaku liza kwahlulwa libe ngamacandelo amabini.

Ngophuhliso lweshishini elitsha lamandla, iteknoloji yamandla aguquguqukayo isetyenziswa rhoqo ngokufanelekileyo, kwaye ii-capacitors ze-DC-Link zibaluleke kakhulu njengenye yezixhobo ezibalulekileyo zokukhetha. Ii-capacitors ze-DC-Link kwiifilitha ze-DC ngokubanzi zifuna umthamo omkhulu, ukucutshungulwa kwamandla aphezulu kunye ne-voltage ephezulu, njl. Ngokuthelekisa iimpawu zee-capacitors zefilimu kunye nee-capacitors ze-electrolytic kunye nokuhlalutya usetyenziso oluhambelanayo, eli phepha ligqiba kwelokuba kuyilo lweesekethe ezifuna i-voltage ephezulu yokusebenza, i-ripple current ephezulu (Irms), iimfuno ze-over-voltage, ukuguquka kwe-voltage, i-inrush current ephezulu (dV/dt) kunye nobomi obude. Ngophuhliso lwetekhnoloji ye-metallised vapor deposition kunye netekhnoloji ye-capacitor yefilimu, ii-capacitors zefilimu ziya kuba ngumkhwa womyili wokutshintsha ii-capacitors ze-electrolytic ngokwendlela yokusebenza kunye nexabiso kwixesha elizayo.

Ngokwaziswa kwemigaqo-nkqubo emitsha enxulumene namandla kunye nophuhliso lweshishini elitsha lamandla kumazwe ahlukeneyo, uphuhliso lwamashishini anxulumene nalo mmandla luzise amathuba amatsha. Kwaye ii-capacitors, njengeshishini elibalulekileyo lemveliso ehambelanayo, nazo zifumene amathuba amatsha ophuhliso. Kwizithuthi ezintsha zamandla kunye nezamandla, ii-capacitors zizinto ezibalulekileyo kulawulo lwamandla, ulawulo lwamandla, i-inverter yamandla kunye neenkqubo zokuguqula i-DC-AC ezimisela ubomi bomguquli. Nangona kunjalo, kwi-inverter, amandla e-DC asetyenziswa njengomthombo wamandla okufaka, oqhagamshelwe kwi-inverter ngebhasi ye-DC, ebizwa ngokuba yi-DC-Link okanye inkxaso ye-DC. Ekubeni i-inverter ifumana i-RMS ephezulu kunye nemisinga ye-pulse ephezulu evela kwi-DC-Link, ivelisa i-voltage ephezulu ye-pulse kwi-DC-Link, , okwenza kube nzima kwi-inverter ukumelana nayo. Ke ngoko, i-capacitor ye-DC-Link iyadingeka ukuze ifunxe i-pulse current ephezulu evela kwi-DC-Link kwaye ithintele ukuguquguquka kwe-pulse voltage ephezulu ye-inverter kukwinqanaba elamkelekileyo; kwelinye icala, ikwathintela ii-inverters ekubeni zichaphazeleke kukugqithisa kwe-voltage kunye ne-transient over-voltage kwi-DC-Link.

Umzobo wesicwangciso sokusetyenziswa kwee-capacitors ze-DC-Link kumandla amatsha (kubandakanya ukuveliswa kwamandla omoya kunye nokuveliswa kwamandla e-photovoltaic) kunye neenkqubo zokuqhuba iimoto zezithuthi zamandla amatsha ziboniswe kwiMifanekiso 1 kunye no-2.

Umfanekiso 1 ubonisa i-topology yesekethe ye-converter yamandla omoya, apho i-C1 yi-DC-Link (ngokubanzi idityaniswe ne-module), i-C2 yi-absorption ye-IGBT, i-C3 yi-LC filtering (icala elingenanto), kunye ne-C4 rotor side DV/DT filtering. Umfanekiso 2 ubonisa iteknoloji yesekethe ye-PV power converter, apho i-C1 yi-DC filtering, i-C2 yi-EMI filtering, i-C4 yi-DC-Link, i-C6 yi-LC filtering (icala legridi), i-C3 yi-DC filtering, kwaye i-C5 yi-IPM/IGBT breast. Umfanekiso 3 ubonisa inkqubo ephambili ye-motor drive kwinkqubo entsha yezithuthi zamandla, apho i-C3 yi-DC-Link kwaye i-C4 yi-IGBT absorption capacitor.

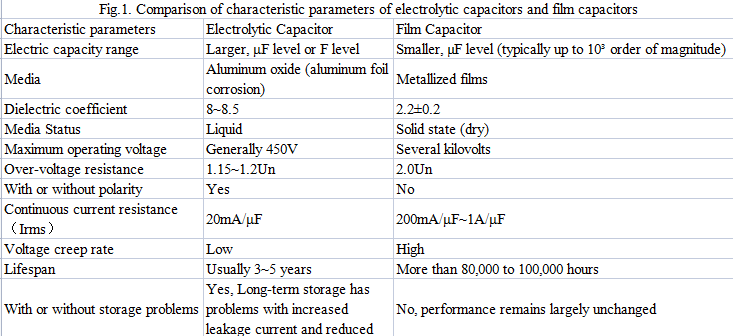

Kwizicelo zamandla ezintsha ezikhankanyiweyo apha ngasentla, ii-capacitors ze-DC-Link, njengesixhobo esibalulekileyo, ziyafuneka ukuze kuthembeke kakhulu kwaye kuhlale ixesha elide kwiinkqubo zokuvelisa amandla omoya, iinkqubo zokuvelisa amandla e-photovoltaic kunye neenkqubo zezithuthi zamandla ezintsha, ngoko ke ukukhetha kwazo kubaluleke kakhulu. Oku kulandelayo kukuthelekisa iimpawu zee-capacitors zefilimu kunye nee-capacitors ze-electrolytic kunye nohlalutyo lwazo kwisicelo se-capacitor ye-DC-Link.

1. Uthelekiso lweempawu

1.1 Ii-capacitor zefilimu

Umgaqo weteknoloji yokwenza isinyithi kwifilimu uqala ukwaziswa: umaleko wesinyithi obhityileyo ngokwaneleyo uyatshiselwa phezu komphezulu wefilimu encinci. Xa kukho isiphene kwindawo, umaleko uyakwazi ukufuma uze ngaloo ndlela uhlukanise indawo enesiphene ukuze ukhuseleke, into eyaziwa ngokuba kukuziphilisa.

Umfanekiso 4 ubonisa umgaqo wokugquma isinyithi, apho i-film media encinci ilungiswa kwangaphambili (i-corona yezinye iindlela) ngaphambi kokuba i-vaporization ukuze iimolekyuli zesinyithi zinamathele kuyo. Isinyithi siyatshintshwa ngokunyibilika kubushushu obuphezulu phantsi kwe-vacuum (1400℃ ukuya kwi-1600℃ ye-aluminium kunye ne-400℃ ukuya kwi-600℃ ye-zinc), kwaye umphunga wesinyithi ujijeke phezu komphezulu wefilimu xa udibana nefilimu epholileyo (ubushushu bokupholisa ifilimu -25℃ ukuya kwi-35℃), ngaloo ndlela kwakheka isinyithi. Uphuhliso lwetekhnoloji yokugquma isinyithi luphucule amandla e-dielectric ye-film dielectric ngeyunithi nganye yobukhulu, kwaye uyilo lwe-capacitor yokusetyenziswa kwe-pulse okanye i-discharge yetekhnoloji eyomileyo inokufikelela kwi-500V/µm, kwaye uyilo lwe-capacitor yesicelo sesihluzo se-DC lunokufikelela kwi-250V/µm. I-DC-Link capacitor yeyesibini, kwaye ngokwe-IEC61071 yesicelo se-electronics samandla i-capacitor inokumelana nokutshayiswa kwe-voltage enzima ngakumbi, kwaye inokufikelela kwi-voltage ephindwe kabini kune-voltage elinganisiweyo.

Ngoko ke, umsebenzisi kufuneka aqwalasele kuphela i-voltage yokusebenza elinganisiweyo efunekayo kuyilo lwabo. Ii-capacitor zefilimu ezenziwe ngesinyithi zine-ESR ephantsi, evumela ukuba zikwazi ukumelana nemisinga emikhulu ye-ripple; i-ESL ephantsi ihlangabezana neemfuno zoyilo lwe-inductance ephantsi yee-inverters kwaye inciphisa isiphumo se-oscillation kwi-switching frequency.

Umgangatho we-dielectric yefilimu, umgangatho we-metallization coating, uyilo lwe-capacitor kunye nenkqubo yokuvelisa zimisela iimpawu zokuziphilisa zee-capacitors zesinyithi. I-dielectric yefilimu esetyenziselwa ii-capacitors ze-DC-Link ezenziweyo ikakhulu yifilimu ye-OPP.

Umxholo wesahluko 1.2 uza kupapashwa kwinqaku leveki ezayo.

Ixesha lokuthumela: Matshi-22-2022